IA01 - NEW PROCESSES WITH ASR EFFECT

ASR: Accelerated Carbide Spheroidisation and Refinement

- Thermal process

- Thermomechanical process

Benefits:

- Reduction in processing times, financial and energy savings, and streamlined logistics

- Replacement of conventional annealing with the rapid ASR process

- Enhanced mechanical properties and extended life of engineering parts

Description:

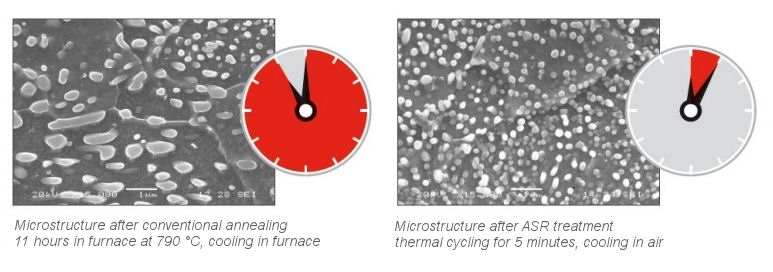

Accelerated carbide spheroidisation leads to rapid softening and is therefore more time-efficient than conventional annealing. At the same time, the combination of rapid carbide spheroidisation and ferrite grain refinement (ASR) can impart improved toughness, wear resistance, strength and, above all, longer lifetime to machine parts.

Relevant fields:

Manufacture and processing of products made of bearing and tool steels, wires, sheet, tubes, bars and sections.

The ASR process provides:

- Carbide spheroidisation

- Fine carbides

- Fine-grained microstructure

- Higher performance of the material – higher strength, wear resistance, toughness

and toughness after quenching and tempering, resulting in longer life of tools and machine parts - Pinning effect (preventing austenite grain growth)