IA06 - METHODOLOGY OF THE EVALUATION OF OPERABILITY

This method relies on microspecimens where minimum amounts of experimental material are required for measuring mechanical properties.

Benefits:

- Evaluation of the operability of equipment and structures will contribute to improved safety and to considerable savings through potential extension of their design life

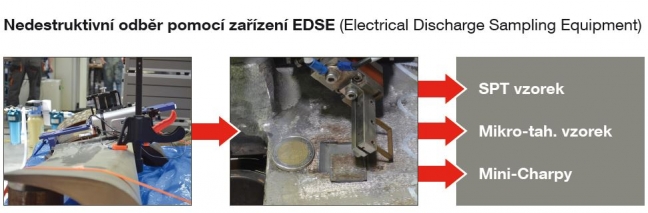

- The current condition of the equipment can be assessed using minute amounts of material taken by means of the EDSE device

- The EDSE equipment can take samples without compromising the integrity of the structure and without subsequent repairs

Description:

Degradation of materials properties can lead to a loss of reliability and safety in equipment and structures in service. Therefore, the condition of a material must be monitored. Conventional testing methods require far too large amounts of material. Taking such samples compromises the integrity of the equipment. “Non-destructive” sampling can be performed by means of the EDSE device. Microsamples obtained with this device can be used for measuring the materials properties and for subsequent evaluation of the equipment operability and ductile failure parameters.

Potential applications

- Power plants (nuclear, thermal, hydro and wind power stations)

- Turbines, rotors, blades and boilers

- Bridge structures

- Oil, gas and steam pipelines

- Rail vehicles

- Other metal structures